BINNING

LED binning is an important process that helps to ensure that LED light products are of consistent quality, colour accuracy, and brightness. It allows manufacturers to produce high-quality LED lighting products that meet the specific needs of their customers. Due to the manufacturing process, there are always deviations in the industrial production of LED lighting. Different characteristics are present in every batch, and every LED. Products with similar characteristics are combined in designated bins in order to prevent large deviations in products. This process is particularly necessary when manufacturing LED lighting within the white light spectrum.

> How are LEDs binned?

LED binning is the process of sorting light-emitting diodes (LEDs) into groups based on their colour and brightness characteristics. This process is essential for ensuring consistency in LED lighting products, such as light bulbs, and maintaining quality standards.

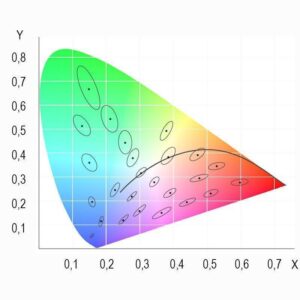

One of the most widely used methods for LED binning is the MacAdam ellipse. Developed by David L. MacAdam in the 1940s, this method is based on the observation that the human eye cannot easily distinguish between small differences in colour under certain conditions.

The MacAdam ellipse divides the colour space into a series of ellipses, each representing a different level of colour variation that is perceptible to the human eye. The smaller the ellipse, the less noticeable the colour variation.

The following are the steps of MacAdam ellipse binning:

Measure the chromaticity coordinates of the LED. Chromaticity coordinates are used to describe the colour of light and are typically represented on a two-dimensional diagram known as a CIE chromaticity diagram.

Determine which MacAdam ellipse the LED falls within. This is done by comparing the chromaticity coordinates of the LED to the boundaries of the ellipses on the CIE diagram.

Assign the LED to a bin based on the size of the MacAdam ellipse it falls within. LEDs that fall within smaller ellipses are considered to be of higher quality and are typically sorted into higher bins.

Test the LEDs in each bin to ensure that they meet the desired brightness and colour temperature specifications. LEDs that fail to meet these specifications may be further sorted into lower bins or rejected altogether.

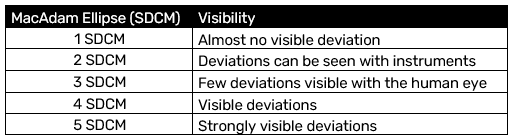

By using the MacAdam ellipse method, LED manufacturers can ensure that their products are consistent in colour and brightness, and that they meet the quality standards required for various applications. 1 MacAdam step and 1 SDCM, Standard Deviation of Colour Matching are the same metric used to show how LED’s vary from one another. There are 7 ellipses in the MacAdam scale. The higher the number, the more deviation.

The human eye can see differences from step 3 to 4. We as a manufacturer only use LEDs from steps 1 and 2, so there are no visible differences to the eye in our fixtures.

> CIE 1931 xy chromaticity diagram

> SDCM explained

SDCM (Standard Deviation of Colour Matching) is a measurement used to quantify the difference between two colours. It is commonly used in the LED lighting industry to describe the colour consistency of LEDs within a batch or between different batches.

SDCM is a unit of measurement that expresses the degree of difference between two colours in terms of standard deviations. It is a measure of how far apart two colours are on the colour spectrum. The lower the SDCM value, the closer the LED’s colour is to the target colour.

To calculate SDCM, the chromaticity coordinates of the LED are compared to the target chromaticity coordinates. The difference between the two is expressed in terms of standard deviations. SDCM is calculated using a formula that takes into account the size of the colour space, the distance between the colours, and the variation in colour perception among individuals.

The SDCM value is used to define the range of colours that fall within a certain level of deviation from the target colour. For example, an SDCM of 3 indicates that the LED’s colour falls within a range of colours that are perceived as having a maximum of three standard deviations of difference from the target colour.

LED manufacturers use SDCM to ensure colour consistency within a batch of LEDs and between different batches. The SDCM value allows manufacturers to specify the acceptable range of colour deviation for a particular LED product. LED products with lower SDCM values are considered to be of higher quality and are often used in applications where colour accuracy is critical, such as in stage lighting or medical lighting.

> ANSI LED binning-standard

The ANSI (American National Standards Institute) binning standard for LEDs is a set of guidelines that helps to ensure consistency in LED colour and brightness. This standard is used by LED manufacturers to classify their products into different bins based on their chromaticity and luminous flux characteristics.

The ANSI binning standard defines the following parameters:

Chromaticity coordinates: These are used to describe the colour of light emitted by the LED. The standard defines a range of chromaticity coordinates within which LEDs are expected to fall.

Luminous flux: This is a measure of the amount of visible light emitted by the LED. The standard defines a range of luminous flux values for each bin.

The ANSI binning standard divides LEDs into bins based on their chromaticity and luminous flux characteristics. Each bin is assigned a letter and a number. The letter indicates the chromaticity range, while the number indicates the luminous flux range.

For example, an LED that falls within the chromaticity range of “U4” and the luminous flux range of “5” would be assigned the bin code “U4-5”. A higher number in the luminous flux range indicates a brighter LED, while a higher letter in the chromaticity range indicates a cooler or bluer colour temperature.

The ANSI binning standard helps to ensure that LEDs used in the same application have consistent colour and brightness, even if they are sourced from different manufacturers. It also helps to reduce waste and cost by allowing manufacturers to optimize their production processes and minimize the number of LEDs that are rejected due to variations in colour and brightness.

> Difference of MacAdam and ANSI

The ANSI binning standard and the MacAdam steps are two different methods used in the LED industry to classify LEDs based on their colour and brightness characteristics. Here are some of the main differences between the two:

Calculation Method: The ANSI standard uses fixed ranges of chromaticity and luminous flux to define each bin. On the other hand, the MacAdam steps method uses the size of the MacAdam ellipse to define the binning.

Chromaticity Range: The ANSI standard defines the chromaticity range within which the LED must fall to be assigned a particular bin. The MacAdam steps method, on the other hand, defines the size of the MacAdam ellipse within which the LED must fall to be assigned a particular bin.

Number of Bins: The ANSI standard has a larger number of bins compared to the MacAdam steps method. For example, the ANSI standard has over 20 bins, while the MacAdam method has typically used only 7 or 10 bins.

Perceived Differences: The MacAdam steps method takes into account the perceived difference in colour, whereas the ANSI standard does not. The MacAdam method defines the size of the ellipse based on the human eye’s ability to perceive differences in colour. This means that two colours may have the same chromaticity coordinates but still be perceived as different due to the difference in the size of the ellipse.

In summary, while both methods are used for LED binning, the ANSI standard is a simpler and more straightforward method, while the MacAdam steps method takes into account the human eye’s ability to perceive differences in colour. The choice of which method to use depends on the specific application and quality requirements of the LED product.

Bleiben Sie auf dem Laufenden

> WANT TO KNOW MORE ABOUT LED LIGHTING?

Want to know more about how our fixtures are made of the best components and how they will best suit your projects? Look at our product pages to see our product range, or contact us. We are happy to help.